Description

Quick Details

- Place of Origin: Shanghai, China (Mainland)

- Classification: Other Adhesives

- Main Raw Material: Acrylic

- Usage: Adhesive for Aluminium composite panel protective film

- Brand Name: Baolijia

- Model Number: BLJ-509

Packaging & Delivery

| Packaging Details | 1000kg/IBC drum, 200kg/plastic drum, 200kg/iron drum |

|---|---|

| Delivery Time | 1-2 weeks |

Adhesive for Aluminium composite panel protective film BLJ-509

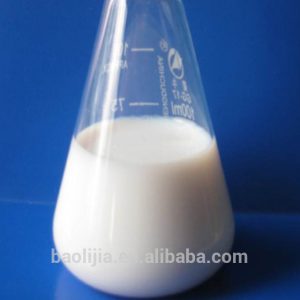

BLJ-509 is a two-component, high viscosity emulsion glue, specially designed for PE protective film. Compared with similar products on the market, it has high stickiness, high peel strength, good water resistance, and excellent deconvolution effect. Compared with the solvent-based glue, it has the advantages of non-polluting, non-toxic, odorless and easy-operating.

Typical Properties:

| No. | Items | Indexes |

| 1 | Appearance | Milky liquid |

| 2 | Viscosity, mPa•S | <200 |

| 3 | Solid content,wt% | 53±1 |

| 4 | PH | 7.0-8.0 |

Glue Features:

High viscosity, strong peel strength, unwinding effect

According to the different protective surfaces, by adjusting the ratio of glue and hardener to produce protective film with different viscosity

Good waterproof performance, suitable for matte aluminum profile surface

The recommended ratio of BLJ-509/ curing agent = 100:0.1.

Operation method:

Under the condition of mechanical stirring BLJ-509, the quantitative hardener is added slowly, and then stirred for 15-20 minutes after the completion of the curing agent is added and homogeneously dispersed with glue.

Notes:

The adjusted glue’s safe use period is 6-8 hours; the adjusted glue should be used up within this period.

After opening the package if it can not be used up by one time, tie the bag to avoid surface conjunctiva, it can not be put under sun exposure, not compatible with the use of cationic additives.

f there is skinning in the grooving, mainly caused by the reason that curing agent is not dispersed completely and uniformly in the glue. So, be sure to use mechanical agitation to increase uniformity of dispersion, and meanwhile using a 200 mesh filter cloth filters out un-dispersed gel slug through while the glue is passing the filter.

The products are stored in 50kg, 125kg or 150kg plastic drums or 200 kg iron-plastic drums or 1000kg/IBC drum. The products are stored in ventilated, dry rooms and avoid direct sunshine. The temperature for transportation and storage of the product is 5℃ – 35℃.The shelf life of the product is 6 months since it is packed.

Remarks: The data above is product characteristics, not the specifications, which not constitute a basis for our legal responsibility. Since the conditions of handling and use are beyond our control, we make no guarantee of results and assume no liability for damages incurred by the suggestions above. Clients should use the product according to the actual conditions.